Pickling of Metal Strips

Pickling with sulfuric acid for nonferrous metals

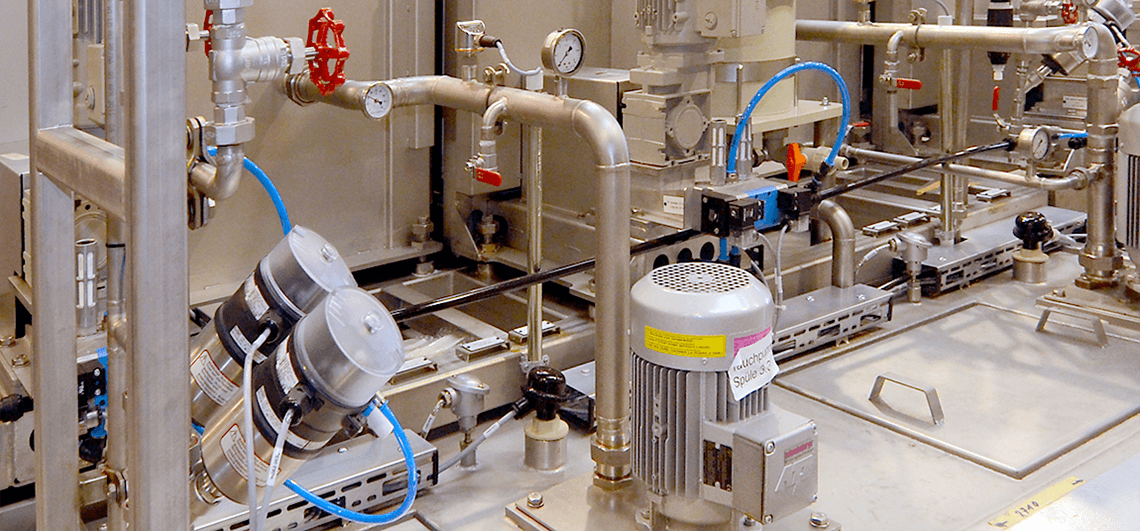

Typically, sulfuric acid is used as a pickling additive to pickle nonferrous metals. To achieve an optimal pickling efficiency, WSP typically uses a spray pickler. Hereby, the strip is impinged with pickling liquid through numerous nozzles. The removal rate of a spray pickler is higher than the removal rate of a bath pickler due to the following reasons:

- Due to the kinetic energy of the spray jet, fresh acid is continuously brought directly onto the metal surface (independent of strip speed).

- This energy additionally supports the removal of oxides (e.g. for brass).

Also in the field of degreasing and rinsing, spray liquids have been established due to these reasons. Ther removal rate can also be influenced by the temperature. If desired, we equip your pickler with an electrical heating. Only the use of additional oxidants (such as hydrogen peroxide) can argue against a spray pickler: the hydrogen peroxide consumtion would be high which would make the processes uneconomical. For these special cases we can also deliver immersion picklers

GERMAN

GERMAN