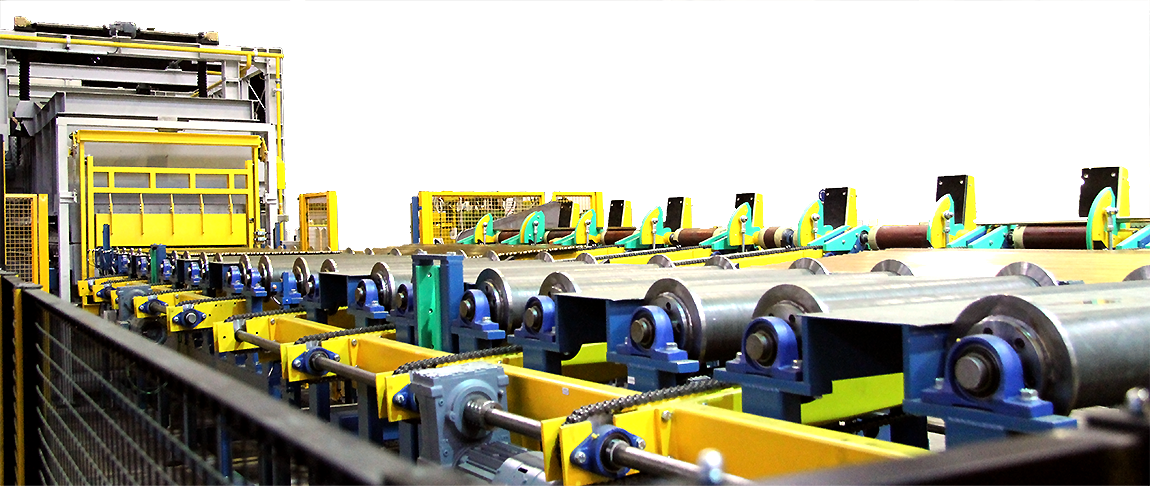

Roller Hearth Furnace

Our roller hearth furnaces are designed for the heat treatment of rods, tubes and profiles both in continuous operation or batch operation at high temperature uniformity and low energy consumption. High heating and cooling rates can be realized due to powerful and highly efficient convection nozzle systems. Our plants are suitable for copper, brass, aluminum and steel.

Annealing atmosphere: air, protective gas. Roller hearth furnaces which are only operated with air can be easily maintained due to a separated furnace housing which is equipped with a lifting device for the upper part.

Examplary Data

Dimensions

| Description | Value |

|---|---|

| Total length of Roller Hearth Plant | 70 m |

| Length of one charge | 9 m |

| Width of roller hearth | 1.200 mm |

| Max. annealing temperature | 1.000 °C |

Cooling Speeds in protective gas atmosphere containing 95 % N2 and 5 % H2:

| material thickness | mm | 5 | 15 | 30 |

|---|---|---|---|---|

| cooling speed | Kelvin/min | 100 | 50 | 20 |

GERMAN

GERMAN