Prepare

Set-up of new switching cabinets, preparation of wiring and mechanical piping

Is the throughput of your floatation furnace not satisfying?

Is the stability of the strip run or the annealing result (e.g. planity) not satisfying?

Is the condition of the furnace zone (usually the inner components) critical so that problems result?

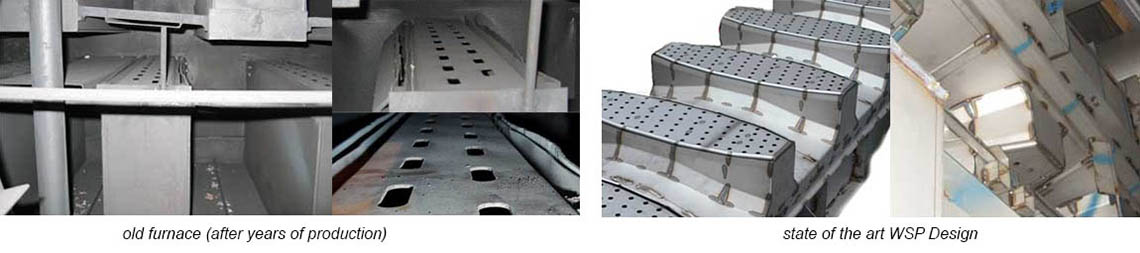

In these cases, WSP can help you! We check your plant and show you improvement opportunities. From minor repairs, exchange of damaged internal parts up to the exchange of the complete plant, we have everything already done. We always make sure that the rebuilding time is as short as possible.

The modern WSP Strip Floatation Furnaces are extremely robust and durable. In particular, we have optimized:

Massive design of nozzle systems, typically 3 mm sheet thickness

Massive design: reinforcements at many components

Massive design: improved geometries, less flat surfaces

Material selection for the individual parts according to temperature and mechanical stress

Maintainability: all WSP Strip Floatation Furnaces are easily accessible and maintainable (e.g. approx. 600 mm passage width in a 650-furnace).

Generally, in addition to the improved durability, we can also enhance the efficiency of your plant. Of course also our nozzle system has become more powerful und offers an improved strip stability.

Set-up of new switching cabinets, preparation of wiring and mechanical piping

Last production day of the old plant

Deconstruction and removal of the old system

Set-up and alignment of new plant

Mechanical and electrical installation and commissioning

Start of production, 1-shift

Standard production, 3-shift

| Old furnace | New WSP Furnace |

|

|

|

|

|

|

Copyright (c) 2021, WSP GmbH; all rights reserved.